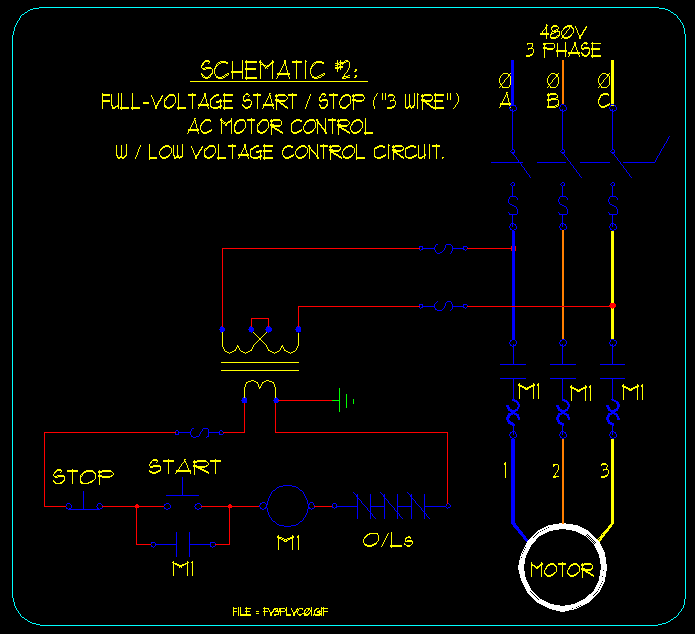

Basic Start Stop Wiring Diagrams are essential tools for understanding the electrical connections in a start-stop circuit. These diagrams show the components and wiring connections involved in starting and stopping a motor or other electrical device. By following the wiring diagram, technicians can easily troubleshoot issues, install new equipment, or make repairs with confidence.

Importance of Basic Start Stop Wiring Diagram

- Helps in understanding the electrical connections in a start-stop circuit

- Guides technicians in troubleshooting electrical issues

- Ensures proper installation and maintenance of equipment

- Provides a visual representation of the wiring connections for easy reference

Reading and Interpreting Basic Start Stop Wiring Diagram

When reading a Basic Start Stop Wiring Diagram, it’s important to understand the symbols and connections used. Here are some key points to keep in mind:

- Identify the components in the circuit, such as switches, relays, and motors

- Follow the flow of electricity from the power source to the load

- Note the wiring connections, including the color-coding and terminal designations

Using Basic Start Stop Wiring Diagram for Troubleshooting

Basic Start Stop Wiring Diagrams are invaluable for troubleshooting electrical problems. By following the diagram and tracing the connections, technicians can quickly identify issues such as loose connections, faulty components, or incorrect wiring. Here are some tips for using wiring diagrams for troubleshooting:

- Check for continuity and voltage at key points in the circuit

- Compare the actual wiring with the diagram to pinpoint discrepancies

- Use a multimeter to test for voltage, resistance, and continuity

Importance of Safety

When working with electrical systems and using wiring diagrams, safety should always be a top priority. Here are some safety tips and best practices to keep in mind:

- Always turn off the power before working on any electrical equipment

- Use insulated tools and equipment to prevent electric shock

- Wear appropriate personal protective equipment, such as gloves and safety goggles

- Follow proper lockout/tagout procedures to ensure the circuit is de-energized

Basic Start Stop Wiring Diagram

Start Stop Circuit – What They Are, Where They Are Used And How To Wire

The Essential Guide to Start-stop Diagram – RAYPCB

Start Stop Circuit Diagram

Basic Start/Stop AC Motor Control Schematics under Repository-circuits

Start Stop Wiring Diagram

How To Wire A Start Stop