Alternator Wiring Connections are an essential component of a vehicle’s electrical system, responsible for charging the battery and powering various electrical components while the engine is running. Understanding how alternator wiring connections work is crucial for maintaining the functionality of a vehicle’s electrical system.

Importance of Alternator Wiring Connections

Proper alternator wiring connections ensure that the battery is charged efficiently and that electrical components receive the necessary power to operate effectively. Without correct wiring connections, the alternator may not function properly, leading to electrical issues such as a dead battery or malfunctioning components.

Guidance on Reading and Interpreting Alternator Wiring Connections

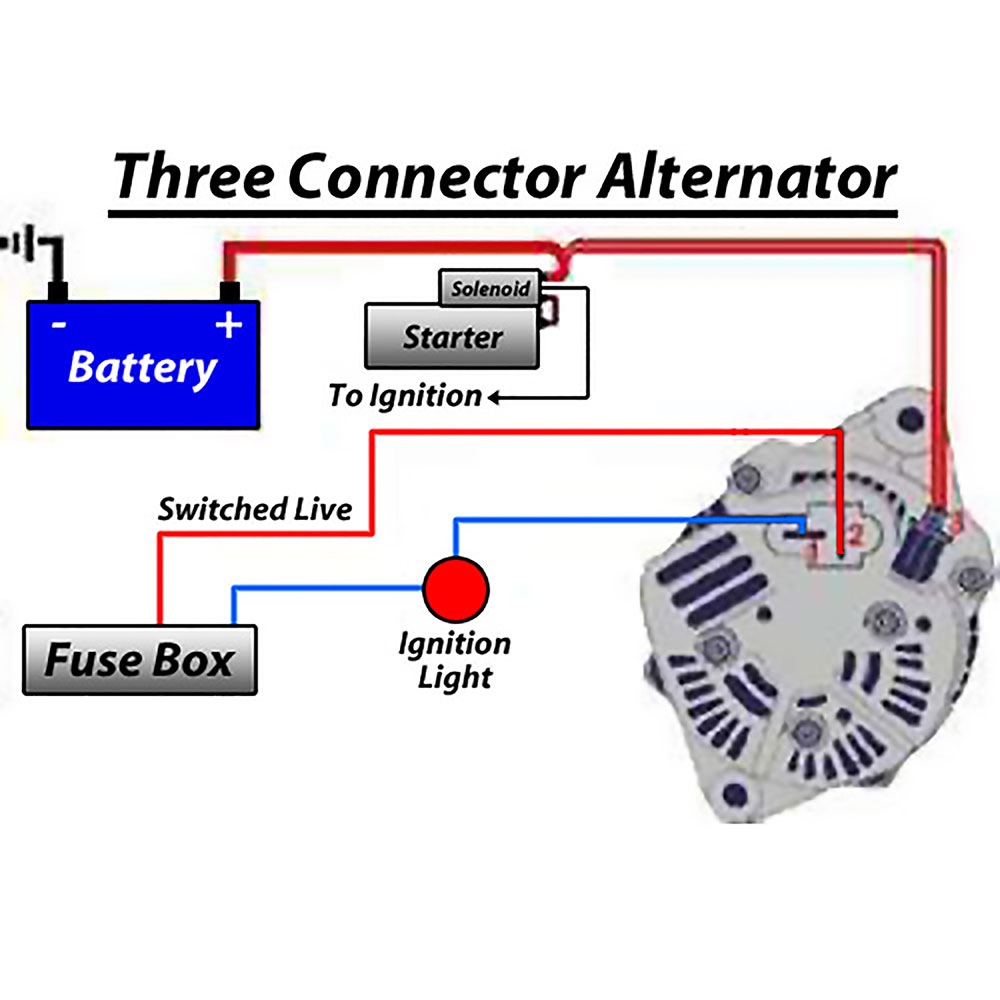

- Refer to the vehicle’s wiring diagram to identify the various wires connected to the alternator.

- Understand the purpose of each wire, such as the main power output, voltage regulator control, and ground connections.

- Use a multimeter to test the continuity and voltage of each wire to ensure proper connectivity.

Using Alternator Wiring Connections for Troubleshooting

When troubleshooting electrical problems in a vehicle, alternator wiring connections can provide valuable insights into potential issues. By checking the continuity and voltage of each wire, mechanics can pinpoint the source of electrical problems and make necessary repairs or replacements.

Safety Tips for Working with Alternator Wiring Connections

- Always disconnect the battery before working on the alternator or any electrical components to prevent the risk of electrical shock.

- Use insulated tools when handling wiring connections to avoid short circuits or electrical hazards.

- Refer to the vehicle’s service manual for specific safety precautions and best practices when working with electrical systems.

Alternator Wiring Connections

Common Delco SI Series Alternator Wiring Diagram | Smith Co Electric

Bosch 24v Alternator Wiring Diagram – Wiring Diagram

24 Volt Alternator Wiring Diagram

Powermaster Alternator Wiring Diagram

[18+] How To Wire A Chevrolet Alternator, Vehicle Alternator Wiring Diagram

![Alternator Wiring Connections [18+] How To Wire A Chevrolet Alternator, Vehicle Alternator Wiring Diagram](https://i1.wp.com/i.pinimg.com/736x/88/5b/81/885b81e7558a8eb81806bc92ee85e97e.jpg)

Alternator Wiring – Electrics – RHOCAR – The UK Kit Car Club